铅螺钉是一种用于高精度致动的机械电力传输。它将旋转运动转换为线性运动。铅螺钉(或铅螺钉)的其他名称是动力螺钉和翻译螺钉。

铅螺钉有时会与螺纹杆混淆。尽管它们看起来可能与未经训练的眼睛相同,但螺纹杆上的螺纹要细得多。因此,增加负载下螺纹变形的风险。

在本文中,我们将仔细研究不同的铅螺钉类型,其设计,用例,优势和缺点。因此,让我们开始。

什么是铅螺钉?

Lead screw is apower transmission linkage用于现代机器。它可以在一小片刻中产生很高的力,从而提供了巨大的机械优势。可以将其视为包裹在圆柱杆上的楔形物。

In applications such as screw jacks and mechanical presses, it is used to create large forces. They also find use in applications needing extremely precise motion transfer and control, such as linear actuators and linear stages.

当螺钉和螺母之间的滑动接触区域高,与其他替代方案相比,铅螺钉具有更多的摩擦损失齿轮火车and连锁驱动器。This characteristic generally limits a lead screw’s use to light- and medium-duty applications.

How Does a Lead Screw Work?

A lead screw works in one of two ways:

- The shaft is stationary and the power is supplied to the nut

- 轴旋转并传递电源到螺母

In the first case, manually applied force or a motor rotates the nut. This pushes the nut along the shaft’s axis. Ultimately, the torque applied to the nut is transformed into linear motion.

In the second case, the nut’s rotational motion is restricted and the screw shaft rotates. The nut moves along the screw axis in the process. Thus, the torque on the screw shaft converts into linear motion of the nut.

Lead Screw Components

铅螺钉本身是许多复杂组件中的一个小组件。但是,即使是基本的铅螺钉也可以分解为三个主要组件/功能。这些都是:

- Screw shaft

- 线程

- 坚果

The screw shaft is a cylindrical rod with threads or grooves along its length. At times, it may be referred to as an ACME rod, buttress rod or square-threaded rod as per the thread geometry. The most common materials used for lead screw shafts are carbon steel, stainless steel and aluminum. PTFE-based coatings are often used in harsh environments for durability and to remove the need for oil and grease.

线程在螺旋轴和存在nut. Although it is not a separate component in itself, the thread’s structure is responsible for converting rotational motion into linear motion. The external threads are in direct contact and mesh with the nut’s internal threads.

The nut is a fairly simple component but does not offer much use by itself. Typically, it will have some means, such as tapped or through holes, to connect it to supporting components like a clamp. The clamp connects the nut to a guide rail, restricting the nut’s rotation and only allowing linear motion. Nuts can be made from plastic orbronze添加自润滑特性。

Apart from these components, lead screws may require additional parts depending on the function. For instance, to control backlash, precision lead screws are fitted with loaded springs that create an axial load to prevent unintended axial movements.

使用您的.STP文件在线获取即时制造报价

引用几秒钟

交货时间很短

分裂交付

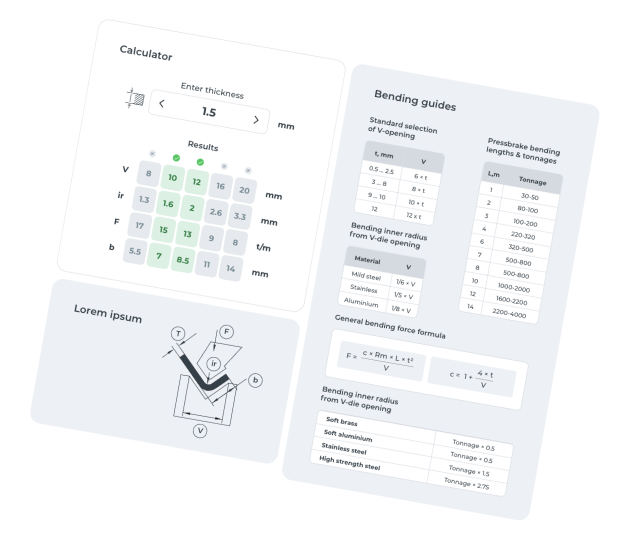

Lead Screw Design

铅螺钉是一个相当简单的执行器,其组件很少,设计简单而有效。但是工程师必须意识到某些铅螺钉术语,以理解,管理和开发使用铅螺钉的产品。铅螺钉设计出现以下术语。

Crest and root

对于铅螺钉,螺纹的顶部被称为波峰。同样,连接到螺杆的螺纹的底部被称为铅螺钉的根。

少校,小和音高直径

Major diameter is the distance of the thread crest from the shaft’s center axis measured perpendicular to the axis. Minor diameter is the distance of the thread root from the center axis. Pitch diameter is the diameter at which the screw threads contact the threads on the nut.

螺旋和铅角

螺旋线与铅螺钉轴的垂直轴之间形成的角度称为螺旋角。较大的螺旋角需要更多的扭矩才能移动螺母,但会导致较低的摩擦损失,从而使设置更有效。

铅角是螺旋角的互补角。它是螺旋线和旋转轴之间的角度。

开始数量

A start refers to the starting point of a thread at the end of the screw shaft. When greater speeds and loads are required of the lead screw system, the screw shaft may have多个开始。它可能有一个,两个或四个开始。具有多个启动的螺钉基本上是独立的螺纹,在轴周围的螺旋路径中彼此平行。

螺丝线和螺距

螺丝引线是在螺母(360°)或轴的一场革命(360°)中通过螺母移动的线性距离。导线越小,螺纹较紧,从而导致更精确的线性运动。

音高是平行于旋转轴平行测量的两个相邻波峰或槽之间的距离。

For single start screws, lead and pitch values are equal. In the case of multiple starts, the pitch is multiplied by the number of starts to obtain the lead.

Types of Lead Screw Threads

铅螺钉根据其螺纹几何形状进行分类。铅螺钉中使用的螺纹必须具有高精度,准确性和强度。铅螺钉中使用的三种最常见的螺纹类型是:

- 方线

- Acme线

- Buttress thread

方线

The square thread has square-shaped threads whose flanks are perpendicular to the axis of the lead screw. This 0° thread angle prevents any radial pressure on components and reduces friction between them.

该设计还可以最大程度地减少螺母和螺钉之间的接触表面。因此,方螺纹具有最低的摩擦损失和最高的效率。结果,它们为相同的尺寸提供了更大的承载能力,或者需要较小的电动机以进行相同的负载转移。万博客户端登陆因此,方形螺纹是运动传输和重载应用中的首选。

方线s are also desirable in products that need to be compact in size while maintaining their functional requirements. However, these threads are the most difficult and expensive to machine out of all the different types. In most cases, they require a single-point cutting tool for fabrication.

Acme线

ACME螺纹是梯形形状的螺纹,螺纹角为29°。它基于帝国标准,但在世界范围内被接受。

该线程是作为平方线的更强替代方案开发的。由于侧面和根部之间的尖角尖锐的角度尖锐,因此平方线在底座上相对较弱。扩大底座会增加强度,并使其更容易加工。与方形线相比,多点切割工Manbetxios具可以更容易地用于机加工ACME线程。

Many times, acme threads are incorrectly referred to as trapezoidal threads. The trapezoidal thread follows the metric standard and has a thread angle of 30°. The exact specifications for trapezoidal threads can be found under DIN 103.

Buttress thread

支撑线是一个三角形的螺纹,仅需要在一个方向上传输力时使用。它在载荷侧面具有7°倾斜度,在后侧面有45°的倾斜度。

如此陡峭的倾斜度使其能够像方形螺纹一样有效地承载载荷,而尾随的侧面则增加了较宽的底座。该线程也非常精确,可用于在一个方向上创建小精确的运动。当沿另一个方向施加轴向载荷时,支撑线表现出较差的性能。

铅螺丝申请示例

Lead screws are available in virtually every size and thus, they serve in a wide range of applications. In day-to-day use, lead screws are found in appliances such as printers, disc drives, lifting equipment and robots.

在行业中,铅螺钉存在于车床,恶习,千斤顶和CNC机器。雕刻,流体处理,数据存储,快速原型,3D打印,测量和检查等过程很大程度上取决于高精度铅螺钉。

The smallest commercially available lead screws can be as small as 0.5 mm in diameter. But for special cases, modern manufacturing methods can fabricate lead screws even smaller in dimensions. These special screws are used in medical devices for automated surgery and drug delivery. The medical industry also requires precision lead screws formedical imagingequipment such as X-ray, MRI, IMRT, PET and CT scan machines.

The Difference Between a Lead Screw and a Ball Screw

Ball screws are an alternative to lead screws offering similar functions. Sometimes they are even categorized as a type of leadscrew. The decision of whether to choose a ball screw or a lead screw can be a confusing one because of the similarities between the two.

球螺钉使用在球轴承中发现的金属球进行运动转移。球螺钉没有内部线,而是将螺丝螺钉中的球螺钉内部的球。这些球适合螺钉上的凹槽,并负责电源和运动传递。球与铅螺钉轴的接触区域很小,导致摩擦非常低。这样可以降低跑步温度并赋予高效率。球螺钉还具有更高的位置准确性,速度和铅选择。

球螺钉的主要缺点是它们很昂贵,没有自锁的特性,并且不像铅螺钉那样抗击。它们通常也比铅螺钉要大一点,并且

如何为您的应用选择正确的电源螺钉

每个应用程序都是唯一的。在做出决定之前,设计师必须了解约束和服务条件。此选择不仅会影响产品设计,而且还会决定整体系统性能。

However, due to the wide variety of screw types and sizes, choosing the right one can be a daunting task. Here’s an overview of the most important power screw features to consider when making the selection.

Load capacity

动力螺钉的负载能力是选择过程中最重要的因素。服务负载会影响许多动力螺钉功能。对于初学者,铅螺钉的直径与所需的推力直接成正比。

There are two types of loads – peak and continuous. Peak load refers to high forces during sudden acceleration or deceleration and can be up to five times the continuous load. Continuous load is a calculated average value (RMS value) and sometimes applies consistently over the nut’s entire travel distance. It also directly affects theL10 life of a component。工程师必须同时考虑两个值,并进行可以管理所有预期负载的设计。

塑料铅螺钉螺母可以舒适地处理高达50公斤的负载,但可以设计可管理多达150公斤的负载。另一方面,青铜铅螺旋螺母可以处理几吨。

速度

电源螺钉选择的第二大因素是速度。螺母旋转或翻译的速度可以通过其螺旋角和直径控制。小螺旋角和大直径将分别降低线性和旋转速度。

低速度意味着低操作温度,避免ting any need for reducing the duty cycle. Operating speed is limited by the critical speed of the power screw. When exceeding this critical rpm (revolutions per minute), excessive shaft vibrations will affect the function and safety of the components. It is generally recommended that the operational speed does not exceed 80% of the evaluated critical speed.

压力速度因子

压力速度或PV因子是一个重要参数,可在电源螺钉上表达实际负载。它是接触表面压力和螺钉轴和螺母之间滑动速度的组合。它是使用聚合物螺母的铅螺钉组件的关键设计参数。

随着负载的增加,必须减少RPM以防止由于摩擦热而导致永久性损害。相反的情况也相反,更高的速度意味着更少的可用负载能力。

通过确保实际的PV值小于所选材料的PV限制,我们可以保证使用更长的使用寿命。

润滑

润滑can be an issue with power screws, especially with those working under heavy loads and/or high speeds. The service environment conditions would need to be evaluated to make an appropriate selection in this regard.

在碎屑高或颗粒浓度的环境中,污染的油脂实际上会引起磨损。但是,润滑对于防止过热,增加负载潜力并改善使用寿命仍然是必要的。

在这种情况下,一种选择是要么清洁颗粒以及重新涂抹膜。或使用干膜润滑剂。即使是具有自润滑特征的青铜坚果也需要阻尼油脂才能使功能令人满意。分析服务环境和功能需求将有助于为您的应用选择适当的电源螺钉。

除了上述因素外,参数(例如反弹,服务寿命,效率,准确性,可重复性,材料,分辨率和所需的自定义程度可以帮助进一步缩小选择铅螺钉时的合适选择。

铅螺钉的优势

- Lead screws are cheap and reliable as they only have a few parts

- They require little to no maintenance

- Smooth and quiet operation

- Capable of lifting heavy loads

- Some power screws have self-locking property

- Low pitch screws can give highly precise measurements, which are vital in machine tool applications

Disadvantages of Lead Screws

- In comparison to other mechanical power transmission methods, leadscrews have a high wear rate

- Not suitable for applications with a very high torque demand

- 他们的效率相对较差