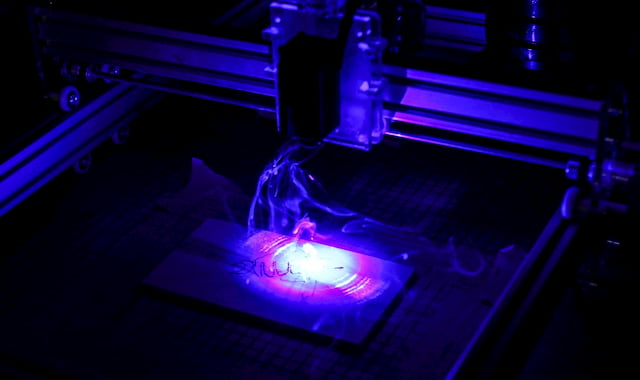

激光适合执行各种操作。激光标记是其中之一。这是使用激光束在各种表面上标记或雕刻的过程。如今,许多应用程序源于这种可能性。

Laser marking is an extremely versatile process. Laser marking is a common term that is used interchangeably for different processes such as ablation, engraving, foaming, colouring, staining, carbonising and so on. Choosing the method depends on the material and quality requirements.

Advantages of Laser Marking

There’s quite a few advantages laser has when comparing it to other possible methods. We are listing the main ones here.

非接触过程

Laser marking is a non-contact process. This means that the equipment does not come into physical contact with the material being marked. It only affects the areas targeted by the laser beam. Consequently, there is no damage to the material by abrasion.

精确

The process of laser marking is extremely precise. One can use it to make marks on very small objects with impressive accuracy. For example, lasers do the markings on printed circuit boards. The high-quality marking is clear and legible.

环境安全

Laser marking is an environmentally responsible way to perform etching as it does not produce any toxic byproducts. The same cannot be said foracid etching。

High Speed

Compared to other methods, laser marking is extremely fast. Using it cuts down the time consumption and therefore the costs. Using the correct laser marking method for different applications can further reduce time required.

低成本

除了设备的电力成本外,涉及激光标记的日常运营成本。该系统几乎不需要人力来处理系统。操作员只需要设置自动完成工作的机械即可。

Adjustable for Different Materials

相同的激光标记系统适用于各种材料。这提供了更大的灵活性,因为大多数行业都使用不同类型的材料。这些包括各种金属,例如结构钢,不锈钢, differentaluminium grades, etc.

Different Processes Using the Same System

The same laser marking system may also be used for laser engraving and other processes with little modification. This is a big advantage as there is no need for extra equipment for different processes and applications.

安全过程

Compared to other methods of etching and marking, laser marking is safer. There are no toxic fumes or waste products formed in the marking process. So it is safe for the person carrying out the process.

但是,最终质量可确保产品在各个领域也可以安全使用。例如,激光标记适用于雕刻牙齿设备。这些产品足够光滑,可以在患者的嘴中使用。

Get your laser cutting quote in seconds

Quote in seconds

交货时间很短

分裂交付

The Durability of Markings

用激光产生的标记是永久性的,具有高对比度。它们可以承受热量,磨损甚至酸。它们是防褪色和防水的。

因此,激光标记适合可靠product tracing。因为随着时间的流逝没有褪色的危险。

Identical Marking for Large Batches

Laser marking can be successfully used to mark a large number of products with a set design in a mass manufacturing setup. It is easy to integrate the system into the production line.

This repeatability is consistent and allows faster project turnaround besides an aesthetically pleasing look.

Applications of Laser Marking

最初,有了1965年第一批激光机的启动,申请仅限于切割。Manbetxios随着时间的流逝,在开发更多过程之后,大量可能的用例就浮现出来。

Now, laser marking processes find use in a wide range of industries. One of them is product labelling.

QR codes, serial numbers, bar codes, dates and part numbers all use lasers for marking. The same applies to best before and expiry dates, maintenance due dates and company logo.

Laser marking may also be used in the process of creating ID cards and smart cards as it is fraud-proof. It is used in the food, automotive, aerospace, medical, electronics, advertising and semiconductor manufacturing industries among many others.

Suitable Materials for Laser Marking

Laser marking is capable of engraving most metals. Lasers are also capable of marking plastics, ceramics, glass, and silicon. Composites, graphite, rubber, and LEDs may be marked in black or any other colour depending on the material. Inscribing precious gems – such as rubies, sapphires and even diamonds – also uses laser marking.

Different Laser Marking Methods

Depending on the application, there are a number of laser marking processes one may choose from. Let’s take a look at some of these methods.

退火通过激光标记

In this process, a laser beam locally heats a metal surface to produce a mark. This localised heating causes structural changes in the metal and results in a colour change. The marking is usually black but it may also be red, green or yellow, depending on the temperature of the heated layers.

激光射线仅穿透20至30 µm进入金属表面。这导致工件的均匀表面。这类退火is usually carried out onferrous metalsand titanium.

退火标记会产生永久性磨损结果。各种行业都使用它。示例包括医疗,牙科,汽车,制造等。退火标记的示例是用于识别和列出机器规格的铭牌。

Laser Engraving

在雕刻中,激光束从表面上去除一些材料。这会以凹陷形式在表面上产生标记。大量材料适合此过程。例子包括金属,塑料,石材和陶瓷。

During laser engraving, the material absorbs heat from the laser, melts and evaporates. The material also reacts with air resulting in a colour change which makes the mark more distinctive. As there are no consumables involved, this technique has low operational costs compared to other methods that use drill bits or special inks for engraving.

碳化

When it comes to marking organic materials and synthetic polymers, carbonising is the way to go. In carbonising, heat from the laser breaks plastic bonds and releases hydrogen and oxygen. Wherever this reaction takes place, the area darkens.

Since the mark formed is grey to blue-grey, carbonising is not always suitable for dark-coloured objects. This will lead to low contrast between the marked portion and the rest of the workpiece. Carbonising is used to mark wood, paper, leather, packaging material, etc.

泡沫

当涉及到颜色浅的标记时,碳化无济于事。对于此类应用,泡沫更合适。在此过程中,激光用于加热材料的表面。

The material melts and gas bubbles are emitted as a consequence. These oxidised gas bubbles form a frothing and reflect light. This method is appropriate for dark-coloured objects.

The mark raises above the surface and has high contrast with the rest of the surface. This discoloration appears only in the case of聚合物。

去除

This laser marking method is especially suitable for coated materials. In this process, the laser removes a layer of the workpiece to reveal the layer underneath (substrate). If the two layers have different colours, it produces a contrast.

涂层材料(例如阳极氧化铝)用这种方法显示出出色的标记。用途包括标签,包装对象和配件。通常与此过程合作的材料是带有涂料,层压板,箔和胶片的金属。

The removable metal absorbs the heat and vaporises where the laser impinges on the surface. This laser etching process also finds applications in the automobile industry where day/night design is preferred. It is imperative that the top coat has a different colour than the base material for efficient and legible marking. Another name for this process is ablation.

染色

Sometimes, the chemical composition of the material can be used to our advantage when it comes to laser etching. The laser beam produces localised heating. This heating incites a chemical reaction. If the byproducts have a different colour, they provide high contrast wherever the laser comes in contact with the surface.

染色needs no penetration. The generation of the mark depends on the oxide layer’s thickness.

Plastic marking uses the staining method. A result of localised heating issoot deposition在材料上。它在表面上给出了深色标记的外观。

What Kind of Machinery is Used for Laser Marking?

各种激光技术可用于激光标记。每个人都有其优点和缺点,选择取决于应用程序,预算和质量要求。基本上,有两种类型的激光器:固态激光器和气体激光器。让我们看看一些可用的选项。

二氧化碳激光标记机

二氧化碳激光标记在密封室中使用二氧化碳气体作为激光源。

顾名思义,二氧化碳激光器是气体激光器。电流将能量泵入气体,然后发射辐射。使用镜子放大该辐射,并集中在材料上进行标记。二氧化碳激光器具有远光质量和相对良好的效率。

CO2 laser machines are suitable for wood, metal, acrylic, glass, paper, etc. It is one of the earliest methods of laser production and still finds a lot of use. It is used for product recognition marking, date stamping, and logos among other applications.

CO2 laser marking machines are also applicable for non-metals. Examples include laser garment engraving, medical packaging, soft drink labelling, rubber marking, plastic marking, leather engraving, and so on.

Fibre Laser Marking Machine

The most popular setup for laser marking today is fibre laser marking. It is a solid-state laser. In this system, an optical fibre doped with a rare-earth element is used as a laser source.

此设置标记更有效,并且更具用途,尺寸较小,并且标记速度更快。它还具有最小的维护和零可消耗量的要求。

所有权的成本并不比其他chines and the system is reliable. It is able to mark even difficult materials, such as PCBs, plastics, nickel and gold plating. It may also be used for sensitive materials and layers.

Fibre lasers最适合激光蚀刻使用退火ing, engraving, and plastic marking processes. They also have a long life of minimum 25,000 hours.

MOPA laser是一种特殊的纤维激光器。MOPA激光器非常通用,因为可以修改脉冲持续时间。这使他们能够使用大量材料。

Nd:YAG Laser Marking System

This method uses Diode Pumped Solid State (DPSS) technology to pump a neodymium or ruby doped YAG crystal with a laser diode to produce laser rays. Its wavelength is exactly ten times smaller than CO2 which prevents it from being absorbed in a variety of materials. Consequently, it can only be used with a limited number of materials.

Unlike fibre lasers, this laser system needs expensive diode pumps. These pumps are wearable and have a life of 8,000 to 15,000 hours. TheNd:YAG laserhas a shorter lifespan compared to the fibre laser.

It can be used to engrave and mark most metals. When set up as a galvo system, it is actually faster than a CO2 laser. But set up time can be long and costly. It also needs more maintenance than other options and does not work well on a lot of non-metallic materials such as wood, acrylic, etc.

They do have excellent beam stability and quality along with higher efficiency though. This system works with coated metals, ceramics, and plastics.