Lasers have been around for a long time but their use in commercial applications is quite recent. It took engineers a while to strengthen laser capabilities to a point where they could compete with traditional manufacturing methods in terms of cost, time and ease of use.

Fibre laser technology, for instance, was first developed back in the 60s. Back then, this technology was still in its nascent phase. Only in the 1990s did it become fit for commercial use. Since then, the technology has come a long way in terms of its applications and efficiency. In the 60s it was possible to only generate a few tens of milliwatts, today we have fibre lasers that can generate over 1000 watts with reliable final properties.

In this article, we will discuss how a fibre laser works, where it is used and why it is often the optimal choice when compared to alternatives. But first, let us understand what it is.

什么是纤维激光器?

纤维激光器是一种使用光纤作为活性增益培养基的固态激光器。在这些激光器中,由硅酸盐或磷酸盐玻璃制成的纤维吸收了泵激光二极管的原始光,并将其转换为具有特定波长的激光束。

To achieve this, the optical fibre is doped. Doping refers to the practice of mixing a稀土元素into the fibre. By using different doping elements, laser beams can be created with a wide range of wavelengths.

Some common doping elements in their increasing order of emitted wavelengths are neodymium (780-1100nm), ytterbium (1000-1100nm), praseodymium (1300nm), erbium (1460-1640nm), thulium (1900-250nm), holmium (2025-2200nm), and dysprosium (2600-3400nm).

Because of such a wide range of produced wavelengths, fibre lasers are perfect for a variety of applications such as万搏app全民彩票平台, texturing, cleaning, engraving, drilling, marking and welding. This also enables fibre lasers to find use in many different sectors such as medicine, defence, telecommunications, automotive, spectroscopy, electrical, manufacturing and transportation.

How a Fibre Laser Works

A fibre laser is named after its active gain medium which is an optical fibre. Any fibre laser machine that produces a well-collimated high-power laser does it in five main stages. These are as follows:

Creation of pump light

收集并进入光纤

Pump light passes through the optical fibre

激光腔的刺激发射

Amplification of raw laser light into a laser beam

Creation of pump light

This is where the energy for the laser beam enters the system. In fibre lasers, we use electricity as the energy source. Diodes known as pump laser diodes convert electrical energy into light energy. In high-quality diodes, the conversion is reliable and efficient and produces light energy only with specific wavelengths.

顺便说一句,低质量的激光二极管是阻碍激光技术进步的主要障碍之一。

在大多数情况下,该泵灯或泵束由多个激光二极管在零件中产生,然后在光纤电缆中耦合。例如,有20W激光器将光纤电缆中11个激光二极管的泵灯组合在一起。

收集并进入光纤

A coupler combines the light from multiple laser diodes into one. This coupler is a part of the optical fibre. It has multiple entry points on one side, each of which connects to a fibre from an individual laser diode.

On the other side, there’s a single exit point that connects to the main fibre. Once all the light is collected, it travels to the laser medium or the gain medium.

Pump light passes through the optical fibre

In the next stage, the laser diode’s light flows through the optical fibre to the laser medium. The fibre consists of two main components: the core and the cladding. The core is made of silica glass and provides the pathway for light. This core is covered by cladding. When the light reaches the cladding, all of it is reflected back into the core.

Fibre lasers invariably lose some power through heat, but the excellent surface area to volume ratio facilitates effective heat dissipation leading to very little heat-related wear and tear.

On further travel through the optical fibre, the light eventually reaches the doped part of the fibre. This part is known as the laser cavity.

激光腔的刺激发射

当激光二极管光到达掺杂纤维时,它会击中稀土元件的原子,并将其电子激发到更高的能级。随着时间的流逝,这导致人口反转,这对于产生标准激光器是必需的。

Population inversion in laser refers to the state of a gain medium in which a greater number of electrons are in an excited state compared to those that are not. It is called population inversion because this is the opposite of the normal state where only a few atoms have excited electrons.

When some of these electrons naturally fall to lower energy levels, they emit photons of only a specific wavelength. These photons interact with other excited electrons, stimulating them to emit similar photons and retreat to their initial lower energy levels. This is the physical process of “stimulated emission” that is a part of the acronym LASER (Light Amplification by Stimulated Emission of Radiation).

The electrons that return to their original relaxed state are re-excited by the incoming light from pump diodes. Eventually, the process reaches an equilibrium between the excited and relaxed electrons, giving us a steady flow of raw laser light. This light needs to be refined for it to be used in different applications.

Amplification of raw laser light into a laser beam

Before using the raw laser light from the doped fibre in applications, it has to be strengthened first. In fibre lasers, this is done by usingFibre Bragg Gratings(FBGs). These gratings replace conventional dielectric mirrors by acting as mirrors of varying reflectivity.

灯在布拉格栅格之间来回跳动。一部分激光灯向一个方向穿过,而剩余的光被反射到激光腔中。穿过光栅的部分变成了激光束。然后通过振荡器(有时是组合器)发送该光束,以提高连贯性,然后作为输出传递。

使用您的.STP文件在线获取即时制造报价

引用几秒钟

Short lead times

Delivery by Fractory

纤维激光与二氧化碳激光器

The main difference between these two processes is the source where the laser beam is created. As explained earlier, fibre laser source is silica glass mixed with a rare-earth element. On the other hand, CO2 laser source is a mixture of gases with CO2 being the main component.

Fibre lasers beat CO2 lasers almost on every front except the initial investment cost. For instance, CO2 lasers cannot cut many materials that are reflective. Fibre lasers handle better a greater number of those reflective metals such as copper, brass,铝和不锈钢。纤维激光器还需要更少的功率,并提供更高的效率。所有这些都是运营成本的一半,是二氧化碳激光器的切割速度(切割薄金属)的五倍。Manbetxios

尽管通常仍然首选切割较厚的材Manbetxios料(高于5mm)的二氧化碳激光器时,纤维激光技术的不断进步正在扩大该技术具有优势的实例。因此,目前,如果您的laser cutting service提供者可以访问这两种类型的机器,以有效地容纳不同的项目。

A fibre laser also provides better beam quality, higher reliability,lower carbon footprint, faster startup time, longer service life and remote processing capabilities. It also requires less maintenance as there are no mirrors or lenses involved. Mirror alignment on CO2 laser machines usually requires a professional or special training of the operator.

它也不需要像二氧化碳激光器那样激光雕刻的陶瓷标记化合物。虽然纤维激光器需要一个greater initial investmentwhen compared to CO2 lasers, they are still a more cost-effective solution in the long run due to the lower Total Cost of Ownership (TCO).

Fibre Laser Applications

由于可能的功率输出范围很广,因此在许多不同的应用中有效地使用了光纤激光器。其中一些是:

Laser marking

通常,发射波长为1064 nm的ytterbium掺杂纤维激光器被认为是完美的laser marking applications。These lasers can mark plastic and metals with permanent, high-contrast marks.OEMs,以及供应商,还需要激光标记机来零件标识,例如条形码,徽标或其他文本。

这些机器可以是手动或自动化的,可以定制以跟上短生产周期。除标记外,还可以使用纤维激光器设备退火, etching and engraving.

Laser cleaning

纤维激光器可以有效清洁油漆,氧化物,生锈等的金属表面。此过程称为激光清洁。该过程可以自动化并针对不同的生产线参数进行定制。

Laser welding

这些激光器的另一个重要应用是焊接服务。纤维激光焊接是最有希望的即将到来的技术之一,由于该过程所提供的各种好处,它正在快速获得市场份额。Laser weldingprovides faster speeds, greater precision, lower deformation, higher quality and efficiency compared to traditional methods.

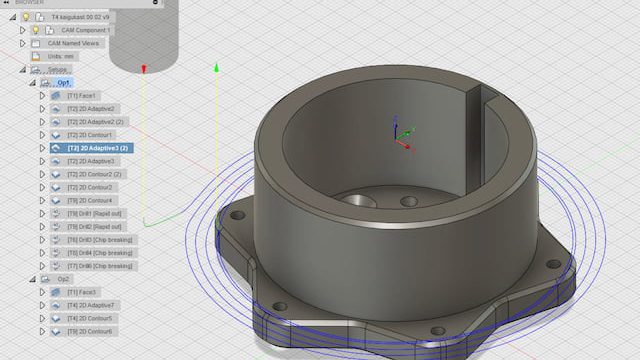

万搏app全民彩票平台

万搏app全民彩票平台是纤维激光应用研究最多的领域之一。它可以以令人印象深刻的边缘质量处理复杂的切割。这使其对于具有近距离公差的零件使其最佳。由于其较长的收益清单,其采用者的采用率正在全面增加。让我们看看下一节中的这些。

纤维激光切割万搏app全民彩票平台益处Manbetxios

与其他激光类型相比,纤维激光器具有多种特征,使其非常适合更广泛的商业用途。我们将这些好处分为四类:

过程的好处

Greater stability

High efficiency

Superb beam quality

易于整合

非接触过程

更快的速度(虽然,二氧化碳激光切割速度straight line)

Safer as the beam is absorbed more readily preventing reflection damage

成本收益

More cost-effective in the long run

High energy efficiency (~75%, the number for CO2 lasers is ~20%)

Reduced wastage

Reduced power usage

降低了操作员的冗余

低工作成本

Equipment benefits

Scalability

Versatility across industries

更紧凑的脚印

长期使用寿命

No periodic mirror realignment

Reduced set-up and downtimes

Eliminated tooling charges

Part quality benefits

Less热损伤to details

Material diversity

Better edge quality

降低残余应力

减少零件污染