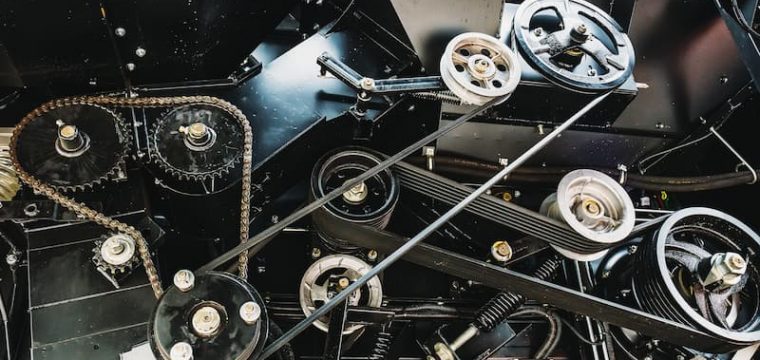

Chain drives are most commonly used to transmit power between two components that are at a greater distance, but they may also be used for short distances. They are one of the five most frequently used mechanical power transmission methods alongsideshaft couplings, gear drives, belt drives andlead screws。每种方法都有比其他方法的几个优点和缺点,这意味着工程师必须在做出最终选择之前要小心。

In this article, we’ll take a look at chain drives and their various types. They are a crucial part of many machines and they can also be used in applications other than just transmitting power, but more on that later. Let’s start from the beginning.

What Is a Chain Drive?

Chain drive is a type ofmechanical power transmissionsystem that uses chains to transfer power from one place to another. A conventional chain drive consists of two or more sprockets and the chain itself. The holes in the chain links fit over the sprocket teeth.

When the prime mover rotates, the chain wrapped on the shaft’s sprocket rotates with it. This applies mechanical force onto the driven shaft, transmitting mechanical power in the process.

One of the main advantages over a belt drive is that a chain drivemaintains a constant speed ratio, thanks to its zero slip feature. There is no lag in power transfer and hence, it serves as a timing chain in applications such asinternal combustion engines。没有滑动也可以确保高机械效率。链驱动器中唯一的损失是由于链条链路和链轮之间的摩擦。

与齿轮相比,链传动方式更多tile when it comes to operating distances. They come into play when shafts are separated at distances greater than that for which gears are practical. Chain drives are efficient at varying distances while still keeping the setup rather compact. They’re found in short-distance applications such as bicycles and long-distance applications such as 5-storey high marine engines. A single chain can power multiple shafts at a time.

Types of Chain Drives

由于发现使用而开发了各种各样的链条驱动器设计在许多不同的机械应用中。它们可以根据我们选择的Yardstick选择分为各种类别。根据其功能进行分类时,链驱动器可以分为三种主要类型。

- Power transmission chain drive

- Conveyor chain drive

- Hoisting and hauling chain drive

Power transmission chain drive

这种类型的链驱动器专门用于在两个轴之间传输功率。大多数产生动力的机器不能在同一地点消耗它,例如带有连接电动机的泵。传输系统通过不同的方法将电力传达给消费者。当将链用于此过程时,它们被称为功率传输链。

Common examples are bikes, agricultural machinery, compressors, engine camshafts, etc. All these applications use chain drives for power transmission.

Conveyor chain drive

连锁驱动器的另一个常见应用是传送带链。输送机使用专门用于材料运输的连锁驱动器。它们具有数百种不同的设计和运动特征,例如低摩擦,高温和耐化学性。它们也可以是反静态的magnetic。

传送带链驱动器可以在包装,汽车,食品和饮料生产,药品和纺织品等行业中找到使用。附件可以安装在输送链中,以使其适应各种用途。

Hoisting and hauling chain drive

Chain hoists are probably the most common piece of machinery used to lift and lower equipment. They can lift massive weights with very little effort using pulleys.

手工链吊船或连锁店是车库,车间,建筑工地,船舶机室和许多工厂中的常见景象。它们可以举起/降低重量高达20吨。吊装链可以是气动,电气或手动的。

We will be focusing on the different types of chains in the next section but since hoisting chains are rather straightforward in their design and field of application, we’ll be covering them here. Hoist chains can be divided into two categories:

- Oval link chains

- 螺柱链路链

Oval link chains

Oval link chains are also known as coil chains. They are commonly used as hoisting chains forlow to medium loadsand are generally meant to be used inlow-speed lifting applications。The chain link is oval-shaped and each one isweldedafter interlocking.

有时,可能会使用链条的方形链接类型,但由于压力分布和扭结问题,通常可以避免它们。

螺柱链路链

螺柱链路链are a better alternative forhigh-load applications。每个链条链路都符合其内部宽度的螺柱。这些螺柱防止扭结并增加强度和耐用性。螺柱链路连锁链在船舶锚和其他重型起重机器中发现使用。

类型的链条在使用

There are many types of chains used in chain drives, each with its own advantages and disadvantages. The five most common types in use are as follows:

- 滚子链(bush roller chain)

- Silent chain or inverted tooth chain

- Leaf chain

- Flat-top chain

- 工程钢链

滚子链

在谈论链条时,滚子链可能是大多数人想到的。滚轮或灌木滚轮被广泛用于运输行业中自行车,摩托车和其他应用的电力传输。它们通常由普通碳钢或钢合金制成。

A roller chain is made up of an inner plate (roller link plate), outer plate (pin link plate), bushes, pins and rollers. The rollers are placed equidistantly between chain links. These rollers engage with the sprocket teeth and transfer power through the chain. An important advantage of roller chains is that they rotate as needed when they come into contact with the sprocket teeth, thus reducing power losses.

在变速箱链中,辊链链路板的高度(在滚筒的每一侧)大于滚子。这样可以防止侧板在操作过程中与链轮接触。除此之外,它们还充当指南并防止滚子链滑下。

For roller chains in conveyors, the roller diameter is relatively larger than the height of the sidebars. This prevents contact between the sidebars and the conveyor track and improves efficiency by eliminating translational friction. Larger rollers also reduce rotational friction.

For greater power requirements, designers can opt for multi-strand roller chains. Having multiple strands permits the use of low speeds and small chain pitches for the same load requirements.

无声链(倒牙链)

Most chain drives are infamous for their high operational noise. In noise-sensitive environments such as enclosed spaces, mines and residential areas, a quieter chain is more suitable. This keeps the disturbance to the surrounding environment under control and promotes worker well-being.

Enter silent chains, also known as inverted tooth chains. A silent chain can transmit large amounts of power at high speeds while maintaining a quiet operation. The chain consists of flat plates stacked in rows and connected through one or more pins. Each link has the contour of sprocket gear teeth on the underside where it engages with the sprocket teeth.

The load capacity for a silent chain increases with the number of flat plates in each link, and so does the抗拉强度and the chain width.

Leaf chain

These are the simplest types of chains in use. They consist only of pins and link plates. The link plates are alternated as a pin link and an articulated link. They don’t mesh with sprocket teeth as leaf chains are designed to run over sheaves for guidance.

Leaf chains find use in lifting and counterbalancing applications. Some common examples of applications using leaf chains are lifts, lift trucks, forklifts, straddle carriers and lift masts. In all of these low-speed machines, the lift’s chain endures high static loads and a small amount of working load. Leaf chains can handle shock and inertia better than other chain designs.

All lift chains must be capable of handling high tensile stresses without elongating or breaking. They must have sufficient ductility to endure fatigue. As always, lubrication and service environment must be given their due thought already in the design process.

Flat-top chain

Flat-top chains are intended only for conveying. They can replace conveyor belts and belt drives as the material can be carried directly on its links. An individual link is usually made out of a steel plate with barrel-shaped hollow protrusions on its bottom side. The links are connected to preceding and succeeding links by passing a pin through these protrusions underneath the links. The nature of these joints allows movement only in one direction.

有特殊类型的平顶链可以侧向弯曲。PIN构造允许侧向向侧向移动,以使传送带链绕曲线。

Flat-top chains are used in low-speed conveyor machines for material transportation in assembly lines.

工程钢链

The engineering steel chain has been around since the 1880s. This chain was designed to handle the toughest environments and the most demanding applications. They were made of hot-rolled steel and sometimes热处理以额外的力量。

工程钢链s are just as relevant today. However, their strength, wear rate, loading capacity and pitch have increased to match present-day industrial needs.

These chains consist of links and pin joints. The clearance between this chain’s components is larger than other chains as it has to handle dust, dirt and abrasives under normal operating conditions.

Most engineering steel chains function as conveyor chains for material handling but some are also used in drives. They can be seen in applications such as conveyors, forklifts, bucket elevators and oil drilling machines.

Use your .STP files to get an instant manufacturing quote online

引用几秒钟

Short lead times

Delivery by Fractory

How to Select the Right Chain Drive for Your Application

With the amount of variety in the form and function of various chain designs, selecting the right chain drive for an application can become a bit overwhelming. The right way to go about this selection is to eliminate unsuitable options by evaluating the chain’s application and features. This will help to narrow down viable options before the final selection. The most important factors in chain drive selection are as follows:

- Loading

- Chain speed

- Shaft layout

- Distance between the shafts

- Service environment

- Lubrication

Loading

When selecting the right chain drive for your application, the most important question to focus on is how much power needs to be transferred. The chain must be able to handle the power produced by the prime mover.

The safety of the crew and the chain drive system depends upon the correctness of the calculations at this stage. It is recommended to work with an adequate factor of safety.

Chain speed

并非所有连锁驱动器都可以处理高速应用。一些连锁驱动器专为低速设计。可以通过进行计算并确保速度在推荐范围内获得规格。该评估将大大缩小可用于应用程序的设计数量。

Shaft layout

大多数连锁驱动器无法与非平行轴一起使用。如果轴不完全对齐,设计师可能必须考虑gear drives作为备选。

Distance between the shafts

It is recommended that the center distance between shafts be in the range of30-50 times the chain pitch。The designer must also ensure that a minimumarc of contact of 120 degreesis obtained on the smaller sprocket. If the number of sprocket teeth is small,at least five teeth must be in contactwith the chain at any given moment.

Service environment

The service environment will dictate the expected resistance of the chain drive to moisture, dirt, abrasives, corrosion and high temperature. It will also affect other parameters such as vibration, noise levels andfatigue strength。例如,在关注噪音的区域,设计师可以选择使用倒置的牙齿链。

Lubrication

大多数连锁驱动器都需要润滑,以使磨损寿命令人满意。链类型,大小,负载和工作速度将决定润滑的需求和程度。根据应用的不同,设计师可能会喜欢手动液,油浴或强制饲料润滑。

有些连锁店是自润滑的,在整个使用寿命中不需要任何外部润滑。这样的连锁店使用用注入油的塑料或金属制成的衬套提供不间断的lubrication during operation.

连锁驱动器的优势

- Able to transfer torque over long distances

- Contrary to a belt drive, a chain drive does not slip

- A chain drive is more compact than a belt drive and can fit into relatively tight spaces

- Multiple shafts can be powered by one chain drive

- Versatile drive that can work at high temperatures and in all kinds of service environments (dry, wet, abrasive, corrosive, etc.)

- It is a low-friction system that guarantees high mechanical efficiency

Disadvantages of Chain Drives

- Cannot work with non-parallel shafts

- 已知链驱动器很嘈杂,也可能引起振动

- Misalignment may cause the chain to slip off

- Some designs require constant lubrication

- An enclosure is usually needed

- They require chain tensioning from time to time in the form of a tightening idler sprocket